MT Magnetising facilities

HELLING Center for Technology

The "Blue Hall"

The HELLING Center for Technology

HELLING manufactures completely equipped testing facilities for surface crack detection according to customer-specific and regulatory requirements. For the area of magnetic particle testing, this includes e.g.

- Crack detection facilities of different size and configuration

- Railway wheelset testing facilities

- Test facilities for specific test objects such as sling chains

- Test tables for testing cylindrical, rectangular or irregularly shaped test specimens

- Test benches for serial testing

- Test benches for training purposes

Wheelset testing system ROD-A-MAT for combined testing of wheelset axle and wheelset wheels with fluorescent magnetic particle testing

Magnetisation bench HELLMAG

At the HELLING Center for Technology, magnetisation facilities especially adapted to specific testing problems are developed. These include various designs of magnetisation benches, e.g., for series testing or training purposes.

Crack test bench HELLMAG Universal 500 AC

Field and current flooding for magnetisation, demagnetisation and pulsed operation

This crack detection bench is controlled by a foot switch. It can additionally be equipped with an 18 L test agent container with hand shower as well as a pump incl. dry-running protection. An appropriately adjustable bypass and flow rate regulation can be installed to mix the fluorescent magnetic particle suspension.

Crack test bench HELLMAG Universal 1000 AC with mechanical clamping of the test object via two quick clamping units and with two individually switchable magnetisation circuits (alternating current flooding / alternating current yoke magnetisation).

The HELLMAG Universal Crack Detection Bench 1000 AC is equipped with an advanced PLC control system. In addition to workpiece management, the control has setup, manual and automatic modes. The system is operated using a swivelling touch panel from the Simatic KTP series.

The facilities manufactured at the HELLING Center for Technology also include testing systems that are adapted to the items to be tested, such as the chain testing facility.

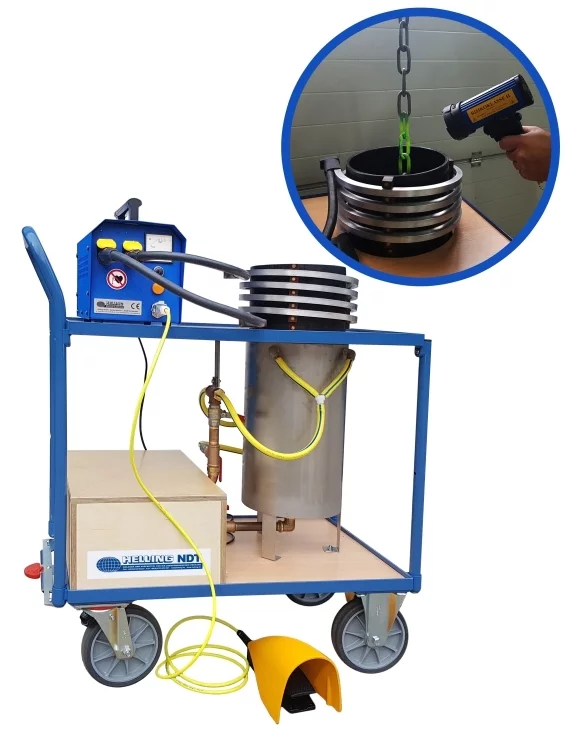

Chain testing facilities

Mobile chain testing facility for testing sling chains in accordance with the German Regulation on Industrial Safety and Health, Section 2BGR 500.2.8, (formerly UVV 18.4.) and DIN 685-5 "Tested round steel chains, individual parts and accessories - Part 5: Use of chain slings and hoist chains". The test facility is equipped with:

- Collection container for the fluorescent test agent

- Flushing device with high performance pump

- Closed magnetising coil

- High current generator

Mounted on a test trolley, the test facility can be easily moved to the test location.

"Kettenprüfeinrichtung 200" -

Testing of sling chains according to BetrSichV and DIN 685-5 with fluorescent magnetic particle testing

The chain testing device "Kettenprüfeinrichtung 200" consists of a mobile test carriage. Of the four wheels, two are steerable and two are braked. The test medium collection container with the integrated rinsing device, the high-performance test medium pump, the closed magnetising coil and the HELLMAG 1100 S high-current generator are mounted on the test trolley. The setup is controlled by a foot switch.

Chain testing device HELLCHAIN 3000 - Testing of sling chains according to the German BetrSichV and DIN 685-5 with fluorescent magnetic particle testing

This test unit for testing sling chains is a mobile test trolley that transports the various components of the system. These essentially include the test medium pump with bypass operation, the test medium tank of approx. 600 L, the closed magnetising coil with spraying ring and the HELLMAG high-current generator. The unit is controlled by a foot switch. The fluorescent indications are made visible by radiation with the battery-operated UV LED hand lamp UV-Inspector 711.

Wheelset testing facility ROD-A-MAT

The wheelset testing system ROD-A-MAT is a complex facility. It enables the wheelset axle and wheelset wheel to be inspected simultaneously by means of two parallel magnetisation systems. The ROD-A-MAT allows a combined magnetic particle testing of wheelset axle and wheelset wheel using a fluorescent magnetic particle suspension.

Wheelset testing facility ROD-A-MAT for combined fluorescent magnetic particle testing (half/segment coil and trapezoidal coil) of wheelset axle and wheelset wheels.

The magnetisation is contactless. A half/segment coil is used for testing the wheelset axle and a trapezoidal coil with several turns for testing the wheel tread.

Segment/half coil for contactless magnetisation of wheelset shafts, test medium: fluorescent magnetic particle suspension.

Trapezoidal coil with 5 turns for contactless magnetisation of wheelset wheels, test medium: fluorescent magnetic particle suspension.

The wheelset inspection system is equipped with a semi-automatic test system with integrated rinsing, UV-A backlighting and the HELLING HCC documentation system.

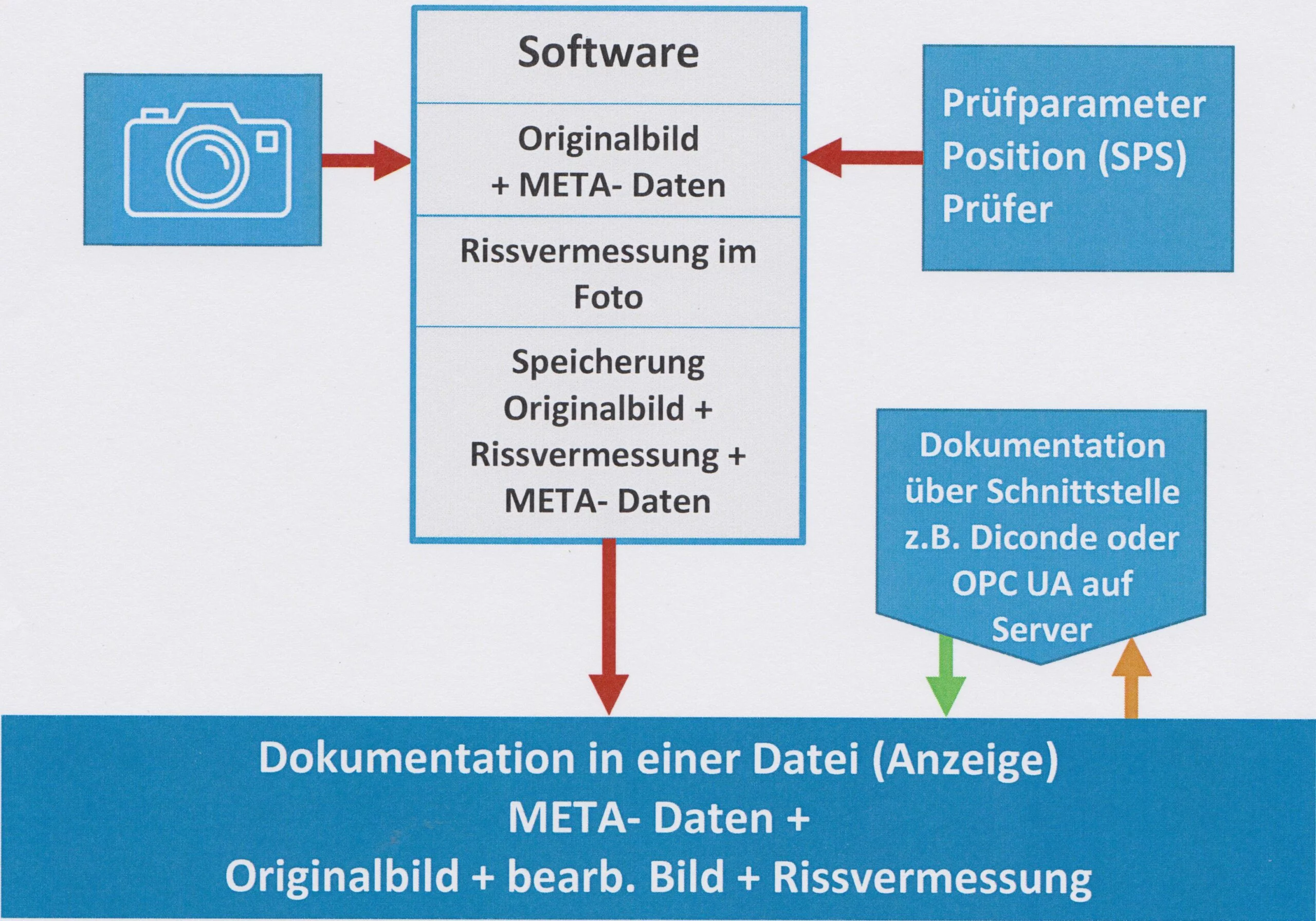

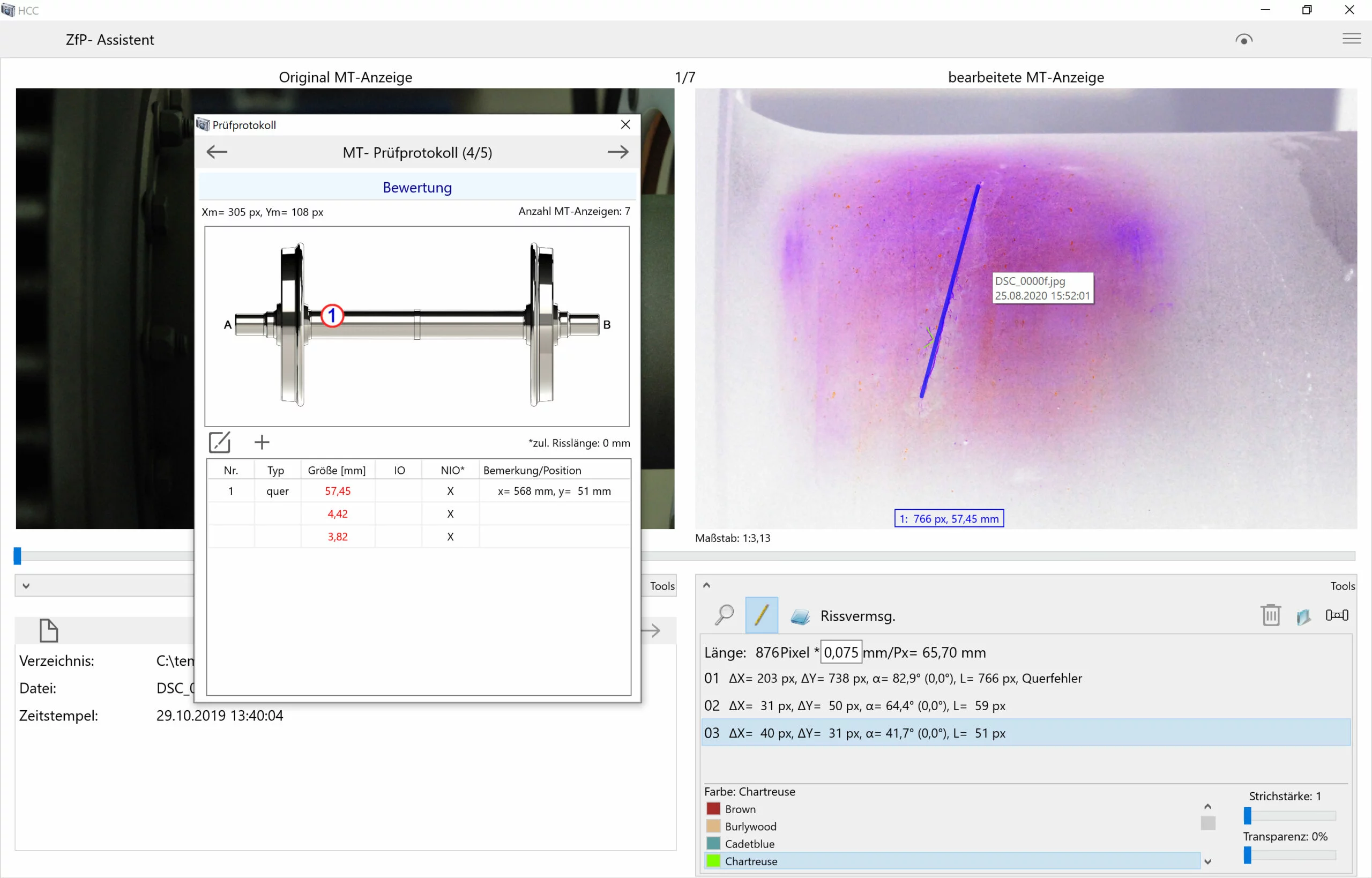

Documentation system HELLING Connect Control (HCC)

HCC documentation system

The HCC system generates a test protocol. This contains:

- Test parameters

- Test data

- Original images of the tested surface

- Copies of the processed indication images

In addition, the Indications are measured and evaluated:

- Position (x/y, inclination)

- Size (mm/pixel)

- Evaluation (IO/NIO)

- Defect type (longitudinal/transverse)

HCC protocol

The system is easy to use and can be adapted to the customer's requirements.

It ensures traceability of the indication acquisition and supports the operator of the plant in optimising the test process control and the analysis of the manufacturing process.

Stationary and mobile magnetisation facilities for the magnetisation of specific test requirements or components such as shafts, wheel sets, stop chains, …

+49 4122 922 - 0

+49 4122 922 - 0  info@helling.de

info@helling.de  Mo. - Do. : 8:00 - 16:30 Fr. : 8:00 - 13:00

Mo. - Do. : 8:00 - 16:30 Fr. : 8:00 - 13:00