UV LED Lamps

Content

- Advantages of UV LED lamps

- UV radiation

- Quality Control - HELLING Optical Measurement Laboratory

- UV LED hand lamps

- UV LED pocket lamps

- UV LED stationary lamps

- Aviation Industry

Certified UV LED lamps

for fluorescent penetrant testing and magnetic particle testing

EN ISO 9934-3, EN ISO 3059, ASTM E3022, Airbus AITM6-1001, AMS2647F and Rolls-Royce RRES - 90061

Advantages of UV LED lamps

UV lamps (stationary lamps, hand lamps and pocket lamps) are now generally equipped with LED. Mercury vapour lamps have had their day. UV LED lamps are used in non-destructive materials testing, e.g., in visual testing (VT), penetrant testing (PT) and magnetic particle testing (MT), as soon as fluorescent test media are used.

Penetrant testing (PT) with a fluorescent test medium

Magnetic particle testing (MT, fluxing) with hand yoke and a fluorescent magnetic particle suspension

Advantages of the UV LED lamp compared to the high-pressure mercury lamp used in the past are mainly:

- Significantly longer operation life

- Significantly lower energy consumption

- Immediate operational readiness after switching on

HELLING offers different versions of UV LED lamps:

- Smart stationary lamps in modular design with many extras

- Handy hand lamps in battery and/or mains operation

- Compact, robust pocket lamps

UV radiation

UV radiation (ultraviolet radiation, wavelengths from 100 nm to 400 nm) is the most energetic part of optical radiation. It is invisible to the human eye. Other sensory organs cannot perceive them either.

The wavelength range is further subdivided according to DIN 5031 "Optical radiation physics and illumination engineering, quantities, symbols and units" into:

- UV-A (400 - 315 nm, long-wave)

- UV-B (315 - 280 nm, short-wave)

- UV-C (280 - 100 nm, extremely short-wave)

UV-A radiation is used in various industrial applications because of its high radiation intensity, e.g., for hardening foils, plastics, varnishes and paints. In non-destructive material testing, the excitation of fluorescent materials (penetrant testing and magnetic particle testing) by UV-A radiation is predominantly used. These lie in the spectral range which is visible to the human eye.

UV-A radiation can cause significant damage to the human eye and skin. It is therefore essential to comply with the limits for permissible irradiation (see "Protection against harmful effects of artificial ultraviolet radiation" - German UV Protection Regulation). Furthermore, it is strongly recommended to always wear UV-A protective goggles when using UV radiation.

UV-A protective glasses Millennia

Black frame and yellow polycarbonate hardcoated glasses

Quality Control - HELLING Optical Measurement Laboratory

Today's safety requirements in industry, especially in plant construction and operation, and in transportation are high. They also address the operational reliability of test materials and facilities in non-destructive materials testing. When performing penetrant or magnetic particle testing with a fluorescent test medium, these requirements are also primarily directed at the reliability and quality of the UV-A light sources used.

HELLING Optical Measurement Laboratory

This applies not only to the standard-compliant development and manufacture of UV lamps, but also to the precise measurement and quality control of the technically advanced UV LED lamps. Industrial sectors such as aviation or automotive have defined the special requirements for the measuring equipment used in their own sets of regulations. They require proof of compliance with these requirements through certification:

- EN ISO 9934-3 " Non-destructive testing - Magnetic particle testing - Part 3: Equipment".

- EN ISO 3059 "Non-destructive testing - Penetrant testing and magnetic particle testing - Viewing conditions"

- Airbus AITM6-1001 "Airbus Test Method for Inspection Processes, Penetrant Inspection".

- ASTM E3022 "Standard Practice for Measurement of Emission Characteristics and Requirements for LED UV-A Lamps Used in Fluorescent Penetrant and Magnetic Particle Testing".

- AMS2647F

- Rolls- Royce RRES - 90061 "Requirements for the control of Ultra-Violet sources utilising Light Emitting Diodes (LED's) for Non Destructive Testing methods".

To ensure reliable and standard-compliant operation of the UV LED lamps, a modern optical measurement laboratory has been set up, in which each UV LED lamp manufactured by HELLING is checked and measured. All UV-A lamps are subject to careful quality control. At the customer's request, a test certificate of the spectral irradiance analysis performed can be issued.

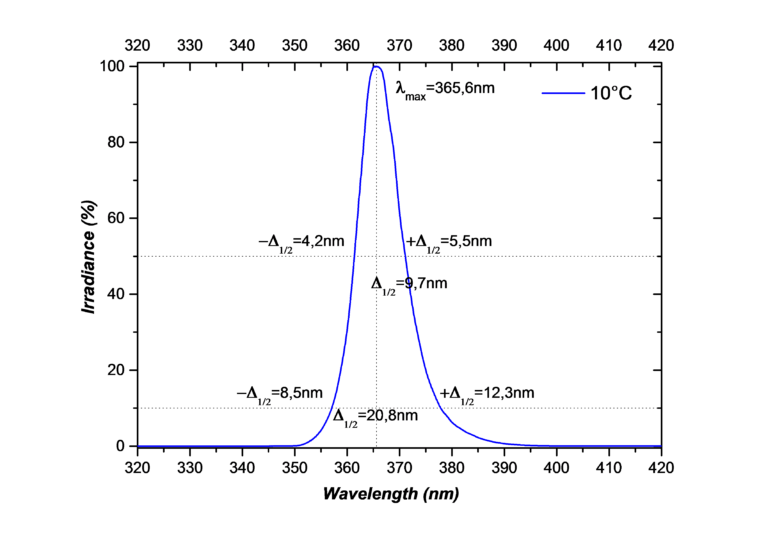

Spectral irradiance of a HELLING UV LED stationary lamp, application area: aviation industry

Performing absolute spectral measurements also allows the determination of the following parameters:

- Maximum value of evaluated irradiance Eeff (determination of the UV-radiation risk class)

- Nominal value of irradiance Ee

- Thermal stability

- Maximum permissible operating temperature

- Emission stability

- Wavelength at maximum

- Half-width

- Longest wavelength at half maximum

- Wavelength drift

- Excitation intensity

The absolute spectral measurements of UV sources take place at different temperatures depending on the requirements.

Further calculations and representations are possible. UV LED lamps from other manufacturers can also be measured and certified in accordance with the normative requirements.

Contact us: Send e-mail

UV LED hand lamps

The battery or mains operated UV LED hand lamps are designed for use in non-destructive material testing (NDT, penetrant testing PT and magnetic particle testing MT). They are also used in criminalistics. In addition, in leak testing (LT, Leak Testing). A prerequisite for leak detection is that the facility to be tested contains oil with inherent fluorescence or oil enriched with a fluorescent concentrate (e.g. Fluo H 800, an oil-based concentrate).

UV LED hand lamps are available with battery operation (above, UV-Inspector 715) and/or mains operation (below, UV-Inspector 150).

UV LED hand lamps with mains operation are very handy. They are supplied with preset or factory-adjustable UV irradiance according to customer request. A white light source is switched on as standard.

To the battery and mains powered UV LED hand lamps

UV LED pocket lamps

Powerful, handy UV LED lamp, certifiable according to ASTM E3022 and RRES 90061

UV LED lamps in pocket format are generally powered by four NiMh rechargeable batteries. They are available in shatterproof splash-proof plastic housing with rubber lamination or in lightweight design with aluminum housing.

UV LED pocket lamps are suitable for use in non-destructive material testing. They are also used in forensics or leak testing (LT). A prerequisite for leak detection is that the facility to be tested contains oil with inherent fluorescence or oil enriched with a fluorescent concentrate (e.g. Fluo H 800, an oil-based concentrate).

robust, splash-proof UV LED pocket lamps

UV LED stationary lamps

The compact stationary UV LED area lamps are characterised by the fact that they

- are equipped with passive cooling

- can be switched on and off again at any time without delay (ON/OFF switch)

- do not need warm up time

- do not have to be in operation permanently - this further reduces the already reduced energy consumption. The service time and thus also the lifetime expectation are increased accordingly.

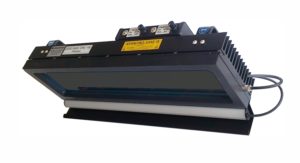

HELLING stationary light ZERO 500/5 IP54

UV intensity continuously adjustable or preset by the manufacturer according to customer specifications.

Filter glass

The following designs are possible:

- Clear glass filter

- MUGLED filter

- UG2A filter

Protection class

Upon customer request, IP65 protection instead of IP54 is available for all UV-LED lamps.

White light bar

Optionally, all stationary lamps can be equipped with an additional white light / red light bar.

UV LED stationary lamps

Aviation Industry

The performance of non-destructive testing in aviation is subject, among others, to the aviation requirements or aviation standards of the respective manufacturer, such as Airbus, MTU Aero Engines, Boeing or Rolls-Royce.

This also applies to UV LED technology. All UV LED stationary and hand lamps manufactured by HELLING for the aviation industry therefore meet the requirements of aviation standards such as

- Rolls- Royce RRES - 90061

- AITM 6-1001

- ASTM E-3022

Stationary lamp ZERO 500-5 IP54 AITM

This stationary lamp fulfils the requirements of aviation industry

As standard, HELLING offers a two-stage system when equipping the stationaty lamps for aviation:

Level 1

- Equipment

The stationary lamp can be equipped with clear glass, MUGLED filter or UG2A filter.

- Defect detection or shutdown

The stationary lamp can be equipped with the indication of a defect by a control LED (e.g., in case of failure of a LED) or with the switch-off function when a defect occurs.

Level 2

- Filter

Equipment of the stationary lamp with UG2A filter. - Defect detection and shutdown

Indication of a defect by a control LED (e.g., in case of failure of a LED) and immediate switch-off. - Temperature monitoring

Switching off the stationary lamp when the ambient temperature drops below 10 °C or rises above 50 °C.

Certificate

Proof of compliance with these requirements from the aviation industry can be confirmed by a certificate on request.

The evidence required for the certificate and the associated measurements are prepared in HELLING's light laboratory using the state-of-the-art measuring technology.

Technical consultancy

Please make an appointment - we are also happy to support you on site !

UV LED stationary lamps for aviation industry