Penetrant Testing

HELLING GmbH

Since 1863

Penetrant Testing

Penetrant Testing

Penetrant testing (PT) is an easy-to-use non-destructive testing method. Penetrants with low surface tension and high capillary effect are used. This allows them to easily penetrate openings in the test part surface such as surface pores or fine cracks with gap widths in the µm range (≥ 25 µm).

Colour contrast penetrant testing of a bearing ring

Fluorescent penetrant testing of a bearing ring

Typical indications that can be detected with the penetrant testing are:

- Cold cracks

- Hot cracks

- Grinding cracks

- Gas pores and clustered porosities

- Spongy texture

- Stress corrosion cracking

Depending on which penetrant is used, a distinction is made between three methods according to EN ISO 3452 Part 2:

- TYPE I Fluorescent Penetrant Testing

- TYPE II Colour Contrast Penetrant Testing

- TYPE III Fluorescent Colour Contrast Penetrant Testing

The basic standard for penetrant testing EN ISO 3452 Part 1 describes in detail how to perform penetrant testing with the various testing products systems.

Process steps of the colour contrast penetrant testing

In the following, the essential steps in performing colour contrast penetrant testing using the red-white method are presented. A solvent-based wet developer (form e) is used.

(1) Precleaning

Mechanical pre-cleaning -

Brushing, sanding, blasting

Precleaning ensures that the surface of the test object is free of contaminants. Impurities can be e.g.: rust, grease or scale. Any indications that may be present are thus made accessible for penetration by the penetrant. Precleaning can be performed:

- mechanical - e.g. brushing, grinding, blasting

- chemical - by means of cleaning agents, whereby these must be removed from the surface after the cleaning process

(2) Application of the penetrant (penetration)

Penetrate -

uniform application of the colored (or fluorescent) penetrant

The penetrant is sprayed onto the dry surface to be tested. The penetrant can also be applied with a brush. Or the test object is poured over with or immersed into the penetrant. The penetration time can be 5 minutes - 60 minutes. This depends on the test conditions (e.g. temperature) and the test object material .

(3) Excess penetrant removal

Removal of excess penetrant, e.g. with a sponge

During excess penetrant removal, the excess penetrant is carefully removed from the test object surface after the specified penetration time. A lint-free cloth or sponge is used for this purpose. The test surface is carefully inspected for residues.

(4) Drying

Drying the test object surface with moving air

Before the developer can be applied, the test object surface must be dry (except when using a water-based developer, form b and c). This is achieved by:

- Wiping with a dry lint-free cloth

- Evaporation

- Forced ventilation (e.g. hair dryer, compressed air)

(5) Application of the developer

Uniform spraying of the white developer

The developer is applied evenly to the test object surface. A thin, homogeneous, white layer is formed. This ensures that the penetrant remaining in the surface openings is bleeding out.

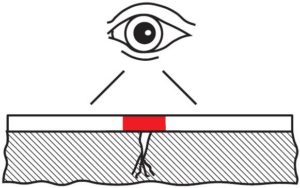

(6) Inspection

Inspection of the test object surface, indications "bleed" out

Immediately after application of the developer, the test object surface is inspected according to the given inspection intervals. The required viewing conditions (see EN ISO 3059, ASTM E1417 or customer specification) are observed.

The test result and the test conditions are recorded by the NDT personnel in the test report. Depending on the test instruction or specification, documentation by fotos or video recordings are made.

Classification of penetration systems according to EN ISO 3452 Part 2

Testing products for penetrant testing are classified by

- Type of penetrant

- Method of excess penetrant removal

- Form of development

(see EN ISO 3452-2 Table 1 above)

Fluorescent penetration systems are classified according to sensitivity levels starting with ½ (very low) to 4 (ultra-high sensitivity).

There are two sensitivity classes for color contrast penetration systems and fluorescent color contrast penetration systems:

| Sensitivity class 1 | normal |

| Sensitivity class 2 | highly sensitive |

Nord-Test

NORD-TEST testing products are used in areas such as

- Mechanical Engineering

- Automotive industry

- Shipbuilding

- Vessel construction

- Metalworking

- Welding technology

Temperature range from -5°C to +50°C.

At low temperatures (from -5 °C to +10 °C), the penetration times must be extended accordingly to achieve the same test sensitivity.

The special specifications in EN ISO 3452-6 "Non-destructive testing - Penetrant testing - Part 6: Penetrant testing at temperatures below 10 °C" shall be taken into account.

For tests at higher temperatures (from +65 °C to +180 °C), the SUPER-CHEK colour penetration system was developed.

The NORD-TEST penetrant system is tested and approved according to

- EN ISO 3452-2

- KTA (Kerntechnischer Ausschuss - Nuclear Safety Standards Commission)

and meets the requirements of

- Lloyd's Register of Shipping

- Bureau Veritas

- Bureau Central Hollandais

- Germanischer Lloyd

- MIL-I-25135 / QPL-25135

- ASME Boiler and Pressure Vessel

- AMS 2644

- ASTM E165

- ASTM E1417

Halogen and sulphur-free tested and certified according to

- ASTM E165-02

- ASTM D516-02

- KWU

- EN ISO 3452-2

Standard-Chek

Standard-Chek ist ein Prüfmittelsystem für die Farb-Eindrinprüfung (Rot-Weiß-Verfahren)

The Standard-Chek testing product system is preferably used in the following areas:

- Mechanical Engineering

- Automotive industry

- Shipbuilding

- Vessel construction

- Metalworking

- Welding technology

Temperature range from -5°C to +50°C.

For tests at higher temperatures (from +65 °C to +180 °C), the SUPER-CHEK colour penetration system was developed.

The Standard-Chek test agents are tested and approved according to

- EN ISO 3452-2

- KTA (Kerntechnischer Ausschuss - Nuclear Safety Standards Commission)

and meet the requirements of

- Lloyd's Register of Shipping

- Bureau Veritas

- Bureau Central Hollandais

- Germanischer Lloyd

- MIL-I-25135 / QPL-25135

- ASME Boiler and Pressure Vessel

- AMS 2644H

- ASTM E165/E165M

- ASTM E1417/E1417M

Halogen and sulphur-free tested and certified according to

- ASTM E165/E165M

- ASTM D516

- KWU

- EN ISO 3452-2

Met-L-CHEK

MET-L-CHEK testing products marked with *** are QPL-AMS2644H listed products.

MET-L-CHEK testing products are used in the following areas:

- General metalworking

- Atomic Energetics

- Welding technology

Temperature range from -5°C to +50°C.

As a special testing products system for high temperatures (52°С - 177° С), the VP 302 penetrant was developed in combination with the D 702 special developer and the R 502 special cleaner.

MET-L-CHEK penetrant testing systems meet the requirements of

- AMS 2644H

- AMS 2647F

- ASME Boiler and Pressure Vessel Section V

- ASTM E165/E165M

- ASTM E1417/E1417M

- EN ISO 3452-2

- NAVSEA-T9074-AS-GIB-010/271

Freedom from halogens and sulfur is tested and certified according to ASTM E165/E165M and ASTM D516 as well as the requirements of KWU and EN ISO 3452.

Penetrant Type I - A,C

Penetrant Type I - B,C,D

Penetrant Type II - A,C

Penetrant Type II - C

Penetrant Type III - A,C

Cleaner

Emulsifier B

Emulsifier D

Developer

TORNIA

Reference blocks and test bodies

PT test kit

PT test facilities

HELLING test facilities for penetrant testing are individually manufactured according to the customer's specification. The facilities are mainly made of stainless steel. The control systems are produced by well-known manufacturers.

A test facility is composed of the following process stations:

- Pre-cleaning

- Washing

- Draying → temperature up to 100 °C

- Cooling → temperature up to 40 °C

- Application of the penetrant

- Washing

- Emulsifying

- Re-washing

- Drying → temperature 60 °C

- Application of the developer

- Inspection

PT test station in tabletop version (standard equipment)

Stationary penetration table with collecting basins and manually operated turntable

The equipment meets the requirements of the following regulations:

- EN ISO 3452-1

- SAE AMS 2644

- MIL-STD-6866

- MIL-I-25135E (replaced by SAE AMS 2644)

European technical regulations regarding occupational health, operational safety and ergonomics are complied with.

If you would like to discuss your specification with us, please send us your request via the watch list or by e-mail to!

We would also be happy to guide you through our NDT exhibition in Hamburg and advise you on your testing problem! More information ...

UV LED lamps

Fluorescent test materials are used in penetrant testing. These are more sensitive than colour contrast penetrants used in the so-called red-white process.

UV LED lamps are used to make the fluorescent indications visible.

UV LED hand lamp

Type UV-Inspector 711 IP65

HELLING is a leading company in the development of handheld UV LED lamps and UV LED stationary lamps.

You can find the latest UV LED lights here...

UV(A) protective goggles

UV LED lamps are used for the inspection of fluorescent indications (in penetrant or magnetic particle testing). To protect the eyes of the test personnel from the harmful UV(A) radiation, it is essential to wear UV(A) protective goggles.

UV safety goggles

Type Millennia

UV protective goggles can be found here...