NDT test facilities

MT test facilities

PT test facilities

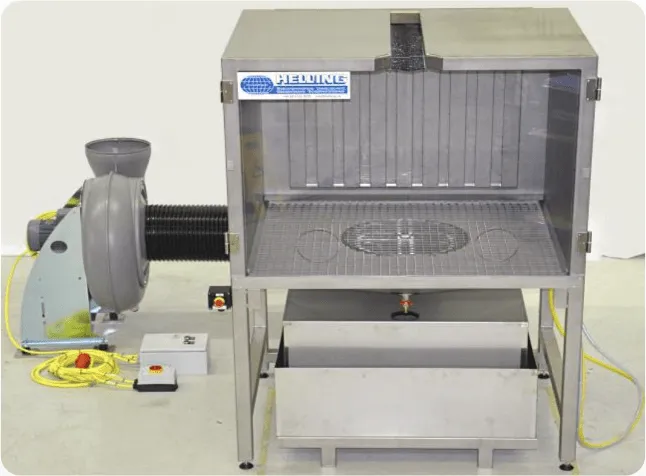

Stationary test facilities - for penetrant testing

HELLING test facilities for penetrant testing are individually manufactured according to the customer's specification. The facilities are mainly made of stainless steel. The control systems are produced by well-known manufacturers.

A test facility is composed of the following process stations:

- Pre-cleaning

- Washing

- Drying → at up to 100 °C

- Cooling → up to 40 °C

- Application of the penetrant

- Washing

- Emulsifying

- Re-washing

- Drying → at 60 °C

- Application of the developer

- Inspection

The equipment meets the requirements of the following regulations:

- EN ISO 3452-1

- SAE AMS 2644

- MIL-STD-6866

- MIL-I-25135E (replaced by SAE AMS 2644)

European technical regulations regarding occupational health, operational safety and ergonomics are complied with.

If you would like to discuss your specification with us, please send us your request via the watch list or by e-mail to!

We would also be happy to guide you through our NDT exhibition in Hamburg and advise you on your testing problem! More information ...