Surface crack testing

Colour contrast or fluorescent penetrant testing and magnetic particle testing

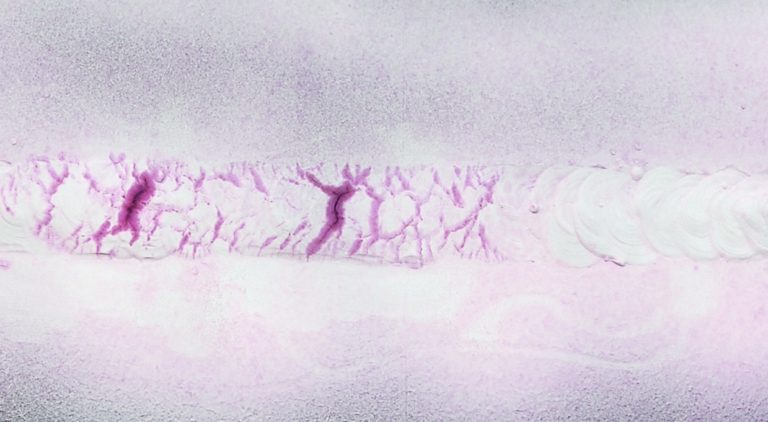

Colour contrast or fluorescent penetrant and magnetic particle testing are non-destructive testing methods for surface crack detection. They allow the detection of surface or near-surface material separations (e.g. cracks, stress corrosion cracks, pores).

Penetrant Testing

Penetrant testing (PT, penetration procedure, capillary process, suction method) is an easy-to-use method of non-destructive materials testing. Neither water nor electricity is required. The penetrants have a low surface tension and high capillary effect. Thus, they can easily penetrate material separations open to the surface.

The penetrant testing process is composed of the following steps:

- Pre-cleaning and drying

- Penetration – application of the penetrant

- Excess penetrant removal and drying

- Dye penetrant testing: application of the white developer

- Inspection

- Final cleaning

You can find more information on penetrant testing here....

More information:

More information on color contrast and fluorescent penetrant testing, test equipment, reference blocks and test bodies, PT test kits and test facilities for penetrant testing.

Magnetic Particle Testing

Magnetic particle testing (MT, MP testing, fluxing) is also a sensitive non-destructive testing method. inhomogeneities on the surface of ferromagnetic materials (e.g. iron, cobalt, nickel and their alloys) can be detected. Near-surface inhomogeneities can also be detected if located and extended appropriately.The process of magnetic particle testing is composed of the following steps:

- Pre-cleaning and drying

- Applying the white background colour (for the black/white process)

- Magnetisation (e.g. with a hand yoke magnet)

- Application of the black or fluorescent magnetic particle suspension

- Proof of magnetisation

- Inspection

- Final cleaning

You can find more information about magnetic particle inspection here....

More information:

More information on coloured and fluorescent magnetic particle testing, test materials, test bodies, MT test kits and test facilities for magnetic particle testing.